- About Us

- News

- Results Released

- Application Scenarios

- Resource Center

- Meeting

Industrial Robot Predictive Maintenance Test Bed

Huawei Technologies Co., Ltd.

Infosys

An industrial robot is an articulated manipulator or a robot that has multiple degrees of freedom. Industrial robots and automated sets of equipment are key devices in the production process and can be used in manufacturing, installation, detection, logistics, and other production stages. Industrial robots are widely used in industries such as those of automobiles, electronics, plastics, foods, and metal processing.

Industrial robots can reduce the defective index and product costs, improve the utilization of machine tools, and reduce the risk of parts becoming defective due to workers' misoperations. Industrial robots also bring a series of benefits, such as reduced labor, reduced loss of machine tools, accelerated technological innovation, and improved competitiveness of enterprises.

Huawei partners with Infosys to build the industrial robot predictive maintenance test bed that leverages edge computing to meet requirements of the customer KUKA. The test bed assists industrial robot manufacturers in achieving digital transformation, transforming from device manufacturers to service providers, and creating new profit growth points. Remotely maintaining robots helps increase efficiency and reduce costs of maintenance, which further reduces end customers' OPEX and improves the production efficiency of enterprises.

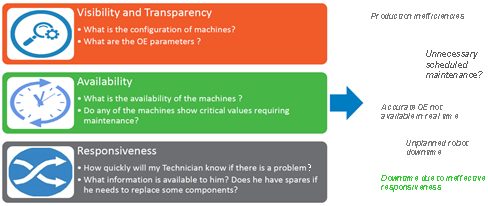

Advanced sensing, network, and Big Data analytics technologies are used to detect the status of robots, achieving:

Status awareness: real-time awareness of robots' configuration parameters and running status.

Robot availability analysis: analysis of the availability and maintenance information based on robots' running status.

System maintenance and troubleshooting: fast fault locating and spare parts supplying, and less downtime.

The lab platform collects, analyzes, and processes running data of industrial robots to achieve status awareness, real-time analysis, fault diagnosis, and predictive maintenance. This benefits both end customers and device manufacturers.

Benefits to End Customers

Predictive maintenance increases reliability of robots, reduces downtime, and improves production efficiency.

If an exception or a fault occurs during machine running, a real-time warning is generated and the fault information can be sent to customers' related personnel by web page or SMS, which can improve efficiency of after-sales service responses.

Benefits to Robot Manufacturers

Predictive maintenance of robots enables real-time detection of robots, and generates alarms in the case of misoperations and reminders for periodic maintenance. Such proactive services help reduce faults.

The platform is used for online remote programming of devices, program uploads and downloads, software updates, and other operations. This effectively reduces the number of maintenance callouts for after-sales personnel.

The platform collects information about exceptions and faults, and diagnoses and analyzes faults. It can remotely provide services for users and solve simple problems, reducing the number of callouts.

The platform can provide real-time core device parameters to the R&D department, facilitating the development of digitalized, integrated, modularized, and smart products to adapt to industry development trends.

The platform helps improve product differentiation, increase product competitiveness, and promote sales. It also assists robot manufacturers in transforming from device suppliers to operation service suppliers.

From 2000 to 2015, the number of industrial robots supplied grew about 12% each year globally. In 2016, the number of industrial robots shipped globally reached 258,900 (85,000 in China), and the number of robots in stock globally was 1,779,000 (332,300 in China). It was estimated that in 2017, the number of industrial robots shipped in the world was about 300,000, of which 100,000 were shipped in China. It is also estimated that the global market size of industrial robots is about US$13 billion.

The downstream end users of robots are classified into those of the automobile industry and general industry. The general industry can be further classified into sectors such as food and beverage, petrochemical and metal, and major appliances. The industrial robots in the automobile industry account for 39 percent of total industrial robots, making the automation level of this industry high. The automobile industry in China has 281 robots per 10,000 workers (there are 1,520 robots per 10,000 workers in Japan and 1,140 robots per 10,000 workers in Germany). In the general industry, the robot density is only 14 robots per 10,000 workers.

The industrial robot predictive maintenance solution brings huge business benefits to the installed base markets and rapidly developing markets. The solution helps manufacturers improve production efficiency and brings edge network upgrade and reconstruction opportunities to ICT vendors.

Over forty years of development, industrial robots have been applied in a growing number of fields. Industrial robots are widely applied in manufacturing industries, especially in the automobile industry. For example, robots have gradually replaced humans in operations such as semi-finished parts manufacturing (including stamping, die casting, and forging), machining, welding, heat treatment, surface coating, loading and unloading, assembly, testing, and warehouse stacking.

The application of industrial robots indicates the industrial automation level of a country. The social benefits of industrial robots are as follows:

Industrial robots can improve production efficiency and reduce costs. One robot can do the same work as at least four to five workers, increasing production greatly.

The use of robots can save raw materials and energy. For example, robots can be used to paint cars, and can achieve the best spraying path, saving oil paints by 20 to 30 percent.

Robots can help improve and stabilize product quality. They can work continuously and stably repeat the operational content while ensuring the highest quality. This ensures high and stable product quality and high consistency.

Industrial robots can replace workers in harsh, hazardous environments and are suitable for monotonous, repetitive, and heavy work. Robots help protect workers and expand the field of human production activities. They enable humans to engage in more creative work and to work in a more comfortable environment, promoting civilized production.

The current robotics application project develops from single robot workstations to robot production lines. The network-based robot controller connectivity technology becomes increasingly important. A robot controller provides the serial port, field bus, and Ethernet connection functions. Robot controllers can be used for communication between robots and between robots and hosts, facilitating monitoring, diagnosis, and management of robot production lines. The industrial robot predictive maintenance solution can help manufacturing enterprises reduce operation and maintenance costs, shorten downtime, and increase the production efficiency.