- About Us

- News

- Results Released

- Application Scenarios

- Resource Center

- Meeting

Time Sensitive Networking (TSN) test bed

Huawei Technologies Co., Ltd.

Latency is becoming more frequently used as an indicator of service quality. As a network increases its coverage and application, latency becomes a bottleneck, affecting services.

Latency on traditional networks is limited to milliseconds. As networks become more complex, latency increases. For example, multi-service processing such as access authentication involves security policies, increasing latency further. The solution based on the existing architecture is no longer capable of reducing latency.

The evolution and integration of communication are widespread in the manufacturing industry, and the network of the manufacturing industry differs greatly from the traditional network.

• Industrial field buses are often used.

− Sensors and drive controllers promote the continuous growth of buses in the industry field. The buses feature simple protocols, low cost, and high reliability.

• The scenario is complex, with varying interfaces, cables, and cabling modes.

− Complex scenarios such as high temperature, medical anti-pathogens, food hygiene, and anti-explosion

− Picotype: M8, Eurotype: M12, Minitype: 7/8

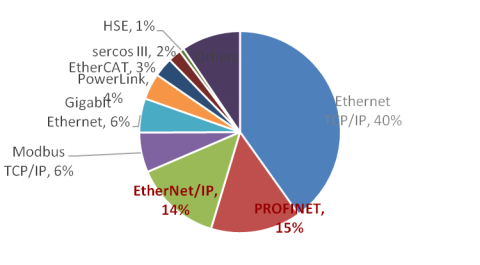

• There are many industrial Ethernet standards, and manufactures influence which standards are complied with.

− Real-time Ethernet, motion control, distributed automation, fault security, and network security technologies correspond to different Ethernet standards.

− Manufactures influence the scope in which standards are used, and there are obvious differences in standards between regions.

Protocols of the traditional industrial lower-layer network are complex. Different industries have different requirements (such as real-time Ethernet, motion control, and distributed automation) on the physical network.

Integrating ICT and OT is crucial for implementing intelligent manufacturing, and TSN is the basic capability.

• Generation of much data: sensor information collection and action execution recording

• Real-time data transmission: protocol interworking conversion and data synchronization

• Real-time data analysis: separation of a large amount of data and local processing of real-time data

• Application ecosystem establishment: industrial cloud building and rapid development of applications

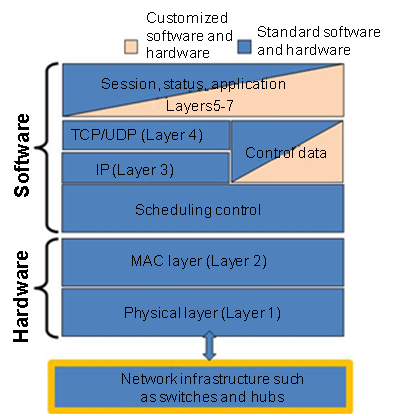

TSN is designed to standardize the architecture at the bottom layer and adapt to various industries at the software layer.

Six key technological points of TSN

• 802.1AS-rev: Timing and Synchronization for Time-Sensitive Applications

• 802.1Qbu: Frame Preemption

• 802.1Qbv: Enhancements for Scheduled Traffic

• Security Remote Password (SRP)

• 802.1Qci: Per-Stream Filtering and Policing

• 802.1CB: Frame Replication and Elimination for Reliability

The TSN test bed verifies key features and capabilities of the real-time industrial network in intelligent manufacturing scenarios.

The test bed uses TSN to reconstruct traditional industrial networks and provide the following benefits:

• Reduced delay: Limit delay to microseconds and achieve clock synchronization in nanoseconds.

• High bandwidth: Provide data transmission at a rate higher than Gbit/s to meet requirements of the industrial Internet for large-capacity data transmission.

• Strong interoperability: The interconnection between devices of different vendors and data collection are simplified by leveraging the standard Ethernet.

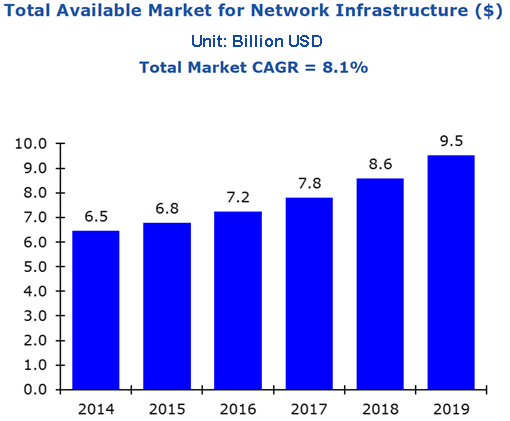

The industrial Internet empowers the traditional industry to abandon the siloed structure, drives the transformation towards a horizontal distributed structure, and enhances interconnection to implement multi-system collaboration. The real-time network plays an important role. It is estimated that the industrial Internet network market will be worth about US$9.5 billion by 2019.

TSN brings huge business benefits to the installed base markets and rapidly increasing markets, improves the production efficiency of industrial vendors, reduces management and maintenance costs, and lays a solid foundation for intelligent manufacturing and flexible production.

Huawei predicts that there will be 100 billion connections worldwide by 2025. The connected systems will generate a large amount of data. For example, the status monitoring solution of the Victoria line of the London Underground generates 32 TB data every day. The analog data will be analyzed and processed to drive correct service decision-making, improving the security, normal running time, and running efficiency.

In some industries, such as transportation, power, and precision manufacturing, important data must be transmitted and shared while being expected to meet strict delay and reliability requirements. This data contains important control and fault detection information, and must be unaffected by other network traffic. The data must be processed and shared immediately and actions must be taken without delay.

Most network infrastructures today do not have the capability to process such sensitive data. Many industrial systems and networks are designed based on the Purdue Model for Control Hierarchy. Multiple reliable bus layers need to be created and optimized to meet requirements of specific tasks. The delay, bandwidth, and service quality of each bus layer vary, which makes it difficult to implement interoperability. It is almost impossible to transmit important data in real time. In addition, the bandwidth of the dedicated Ethernet network is limited, and the hardware needs to be improved.

TSN meets the requirements of the next-generation industrial system, and improves the operating machine, grid, and transportation railway systems, and contributes to the industrial development of smart manufacturing and smart grid.