- About Us

- News

- Results Released

- Application Scenarios

- Resource Center

- Meeting

Edge Computing Lab Platform for Smart Security Supervision

●iSoftStone Information Technology (Group) Co., Ltd.

●Intel Corporation

●Huawei Technologies Co., Ltd.

Secure production informatization is not well established in China and there is a lack of security supervision methods. Platforms for secure production supervision and emergency command have not been established in most regions of China, preventing these regions from providing support and assurance for implementing the principles of "putting safety first, focusing on prevention, and implementing integrated management of secure production informatization". After accidents occur, issues such as unclear secure production situation, slow response, and intermittent information transmission cause difficulties in implementing scientific, ICT-based, and refined security management, as well as insufficiency of enforcement of secure production laws. Monitoring and supervision of secure production cover a wide range of objects and follow a continuous process that is always changing. Traditional means cannot meet the requirements that all levels of security monitoring organizations have for secure development and duty performance, or obtain the front-end secure production data and situation updates, and therefore cannot provide instant guidance for the front-end secure production. Secure production informatization and edge computing urgently need to be integrated. It has been proven that the traditional mode for secure production supervision cannot solve the secure production problems from the root. Prevention methods based on modern technology must be adopted to better perform the security supervision duties.

ICT-driven secure production is the fundamental guarantee for the supervision of secure production, emergency management and rescue, and coordinating rapid, accurate, and efficient running of services. Secure production driven by edge computing lays the foundation for the interconnection of all levels of secure production information and is an important means to implement the strategy of 'using technology to enhance security'.

Currently, there are the following problems in secure production and supervision in China:

●Production accidents frequently occur, causing a large number of personal injuries and property loss.

●Secure production supervision cannot be put into practice. Without a key supervision object at the front end, the supervision policies are hard to implement.

●Secure production supervision focuses on stopping attacks after they occur. Lack of front-end support causes poor risk prevention, forecast, and control.

●There is no closed-loop management for secure production supervision services. Feedback is rarely received after upper-level departments issue a document to lower-level departments. The supervision result cannot be assessed.

●Absence of front-end services in secure production supervision. "Data collaboration" of secure production has not been formed.

The software and hardware products are designed and produced to provide overall solutions and services to tackle the informatization development difficulties at the core of secure production based on the country's guidelines and requirements for development of secure production informatization. The following problems will be solved:

●Collecting real-time front-end data for secure production

●Tamper prevention for front-end secure production data

●Data transmission

●Supervision barriers among multiple industries at the front end of secure production

●Effective utilization of information after acquisition

●Unified supervision of production safety information at the front end

●Absence of data integration in the secure production supervision sector

The platform can be applied to secure production supervision of dangerous chemicals, fireworks, coal, non-coal minerals, and key industrial, commercial, and trading companies by all levels of security supervision organizations, security committees, and corporations. For example, you can use video edge processing technologies to discover risk events such as a fire, violation of dress code for security protection, and overstaffing at operation sites, and generate the alarm.

The lab platform collects and analyzes the secure production data systematically to implement perception of the final status, real-time analysis, decision-making support, precise location, and learning and improvement. The following problems are solved:

●Collecting real-time secure production data: The platform overcomes the problems such as varying enterprise data interfaces, and the inability to quickly acquire data from enterprises and related government offices concerning sources of hazard and security risks during production, transportation, and storage. The subsequent procedures can therefore be guided, monitored, examined, and managed in a targeted way.

●Tamper prevention of secure production data: The platform obtains various types of hazard sources and security risk data from enterprises and related government offices in the process of production, transportation, and storage. Data is stored both on local disks and on the cloud using patented technologies to prevent enterprise tampering, forming a black box of data.

●Supervision barriers between multiple industries at the front end of secure production: The platform releases the modules and products for dangerous chemicals, fireworks, coal mines, non-coal mines, and key industrial, commercial, and trading companies based on their features, implementing comprehensive supervision.

●Data transmission: The platform rapidly transmits the risk information such as hazard sources and security risks in the process of production, transportation, and storage from enterprises and related government offices to secure production supervision departments. Various types of data, including text, audio, video, and images, can be effectively integrated to form comprehensive information, which can be stored locally and uploaded to the cloud.

●Effective utilization of obtained information: The platform can implement intelligent analysis based on the warnings, forecasts, and accidents generated at the front end and provides coping strategies and solutions. By analyzing the front-end data and Big Data of secure production on the cloud, the platform provides comprehensive secure production data services for the customers.

●Unified supervision of production safety information at the front end: The platform deploys the integrated secure production machine to shift the supervision services and data processing to the front end, integrating network, computing, storage, and application capabilities and providing front-end supervision services.

●Lack of data integration in the secure production supervision sector: The platform provides all-in-one security production data solutions and services, including access of industrial data, data storage and transmission, data analysis, and data services. The platform also innovates secure monitoring and supervision modes. The management of secure production, particularly for companies of major hazard sources, shifts from "post-event supervision" to "real-time systematic supervision".

The lab platform leverages features such as comprehensive data processing, early warning closing, video surveillance, and on-duty report to implement enhanced supervision deterrence, perform electronic covert visits, and form a black box of data and a think tank. Enterprises eventually fulfill their obligation of implementing secure production. The supervision department becomes more efficient and the probability of emergencies occurring is reduced.

●Front-end devices collect all the analog values, Boolean values, and buses of various sensor interfaces during secure production, interconnect with the DCS, and process the data systematically.

●During secure production, front-end devices collect image information from various types of network cameras and analog cameras, making surveillance more visualized.

●Front-end devices combine watermarks with secure production data and secure production video signals using patented technologies and store data in mixed code stream to prevent data interception.

●Front-end devices implement early warning closing, alarm linkage, and on-duty report for secure production of enterprises.

●The front-end data is collected in different time segments, analyzed in real time, and applied intelligently. Invalid data is filtered out.

●Data convergence is implemented at the front end. Data convergence, data analysis, and intelligent computing run on a unified integrated device platform, which integrates with cloud data deep learning to implement edge computing.

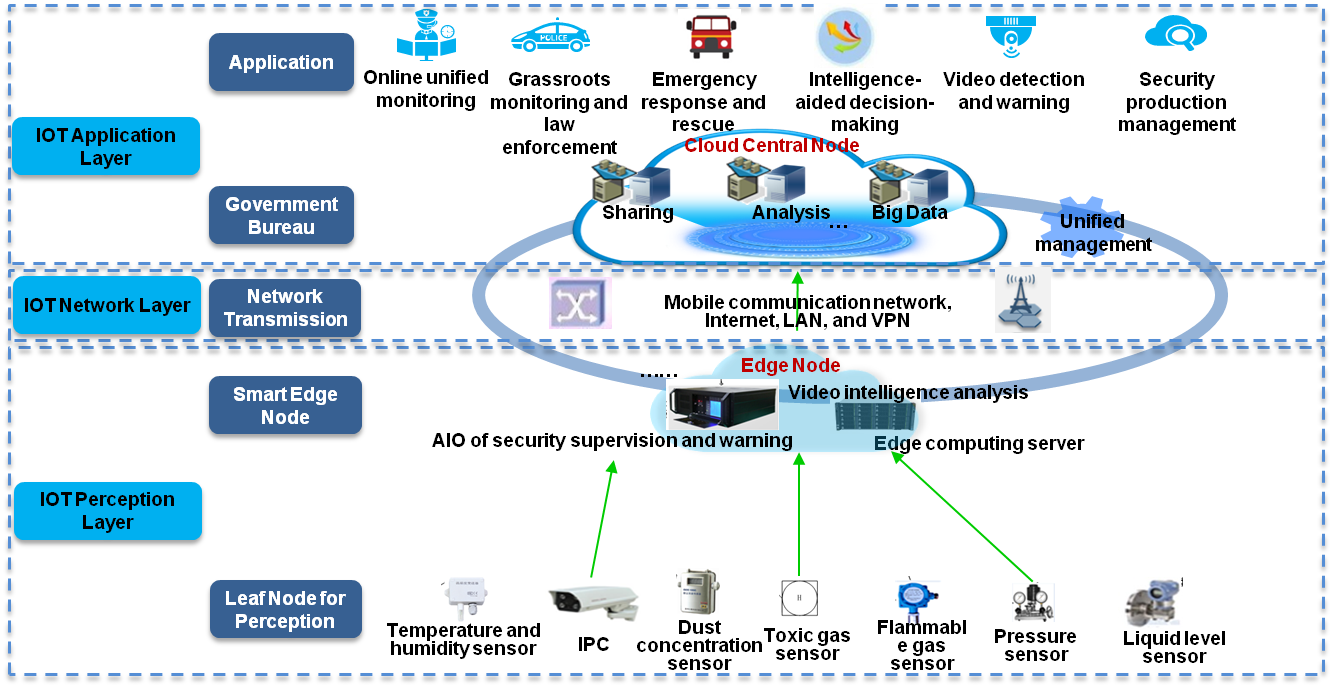

Figure 6-1 Smart security supervision lab platform system architecture

During China's Eleventh Five-year Plan, the State Administration of Work Safety Supervision initiated investment in secure production informatization of the safety supervision sector totaling CNY 4.7 billion, not including the investment from local governments. Of this investment, the State Work Safety Information System Project (Jin'an) phase one costs CNY 270 million (158 million invested by the state, and 115 million auxiliary investment from local departments).

During China's Thirteenth Five-year Plan, state-level investment has created a huge market space for the secure production informatization. The State Administration of Work Safety Supervision is expected to invest CNY 3 billion in new Work Safety Information System (phase one). In addition to investment from local departments, in the next few years, investment in industrial informatization initiated by the State Finance Ministry will be tens of billions of CNY. In addition, the special fund for risk source management in production under the State Administration of Work Safety Supervision, which amounts to CNY 8.9 billion, has been approved by the National Development and Reform Commission. In this fund, CNY 3 billion is used for informatization.

At present, there are about 11 million companies in China. According to the statistics from safety supervision departments in the Twelfth Five-year Plan, there are 22,887 dangerous chemical manufactures in China, and many more companies that store, operate, or transport these chemicals. There are also 99,629 non-coal mining companies, thousands of firework producers, over 12,000 coal mines, and over 45,000 key industrial companies.

Based on the preceding data, the lab platform will create a market worth of billions of CNY in the next few years.

President Xi said: "Development should never be pursued at the cost of safety." This is the principle of secure development that President Xi has constantly emphasized and also an important part of the general security specified in the "overall perspective of national security". Full-society integration of informatized supervision mechanism and platform provides support for decision-making in secure production, predicts the development trend and offers warnings, increases the security handling capability, and reduces the human and property cost. These are also beneficial for social development and public safety.