- About Us

- News

- Results Released

- Application Scenarios

- Resource Center

- Meeting

Industrial robot edge computing controller test bed

SIASUN Robot & Automation Co., Ltd.

Current robot controllers provide motion planning and control, and also specific industrial applications. These industrial applications are tightly coupled with basic robot control, which impedes their development, upgrade, and conversion. In addition, robot controllers have limited interface and computing capabilities, which hinders the access and control of peripheral devices such as PLC modules, sensors, smart meters, and smart I/O modules.

One objective of the edge computing controller test bed is to divide robot controllers into edge computing controllers and motion controllers, in order to decouple applications from the motion control function. Motion controllers provide motion planning and control, and also standard interaction interfaces to edge computing controllers, which provide the following functions:

▲Standard robot services, including security, monitoring, and smart diagnosis

▲Specific industrial application software packages such as stacking, spot welding, and arc welding technical packages, and extended robot services such as multi-robot coordination and dispatching

Another objective of the edge computing controller test bed is to improve the interface and computing capabilities of robot controllers so that the controllers can quickly exchange data with peripheral devices such as PLC modules, sensors, smart meters, and smart I/O modules. The edge computing controller leverages its strong computing capabilities to control workstations or production lines, improving robots' availability.

To meet the two preceding objectives, edge computing controllers require three platforms: communication, data, and application. The robot communication platform enables edge computing controllers to easily exchange data with devices such as PLC modules, sensors, smart meters, and smart I/O modules. The robot data platform effectively collects and manages the data on robots and environments (such as workstations) for industrial application statistics and analysis. The robot application platform carries robot services (such as monitoring, smart diagnosis, and security) and integrates technical packages (including stacking, dispatching, spot welding, and arc welding) for expanding industrial robot application fields and improving the informatization level and quality of manufacturing services.

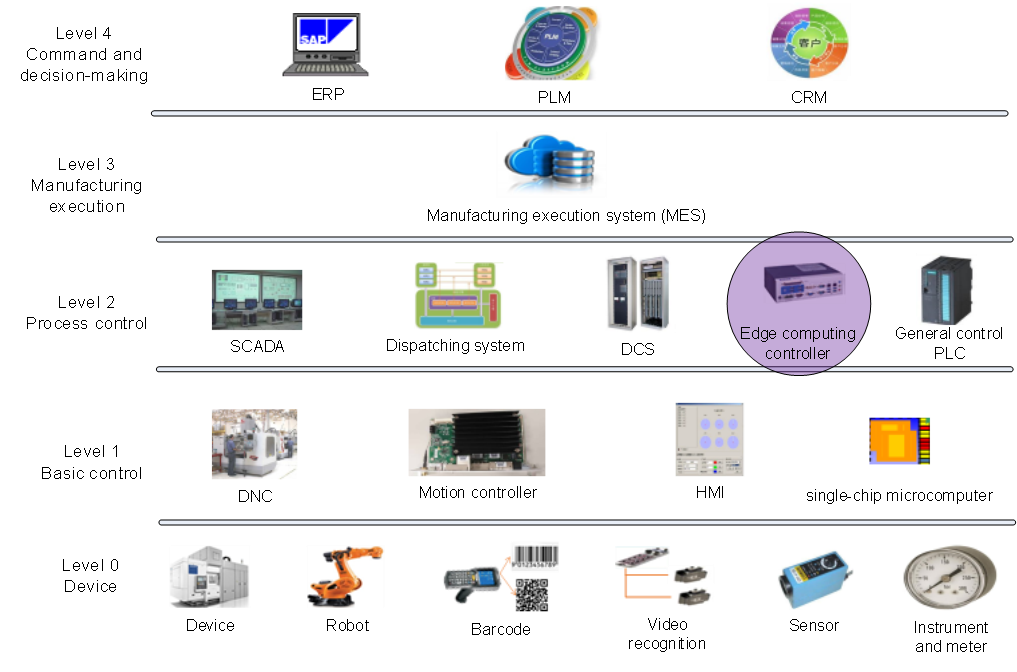

Industrial robots are mainly used in manufacturing workshops. Figure 4-1 shows a reference model of a manufacturing workshop control system (referencing the ISA-95 manufacturing control and dispatching model). Robots are used as execution devices at Level 0 and motion controllers as a direct control system at Level 1. Edge computing controllers provide functions such as process control and management monitoring at Level 2. The edge computing controllers collect and monitor data on lower-level direct control devices, control processes, and require design and development of data exchange, data storage, and application control.

Figure 4-1 Levels of a manufacturing control system

Expected Outcome

The edge computing controller lab platform integrates connections between smart manufacturing devices, sensors, and meters, and collects operational data on industrial robots and peripheral devices. On this basis, the lab platform integrates application services such as robot technical packages, smart maintenance and diagnosis, monitoring, and robot management, achieving the following expected outcomes.

Benefits for Customers

1. Facilitates configuration of workstations or production lines with industrial robots, and simplifies robot system integration.

2. Provides one-stop services, including robot monitoring and maintenance, and reduces costs of the service construction for production lines or workstations.

3. Robots are more flexible, and robot applications can be switched by switching technical packages.

4. Improves robots' local computing capabilities. Distributed data storage and computing provided by multiple edge computing controllers can effectively improve robots' edge computing capabilities. Users can also avoid building complex computing applications, computing servers, and systems, reducing costs.

5. Improves industrial robots' maintenance and management efficiency.

6. Provides interfaces connecting industrial robots to cloud services, improving robots' informatization level and enabling users to quickly deploy a cloud service platform and connect devices to IoT.

7. Integrates various application technical packages, including spot welding, arc welding, stacking, dispatching, security, and vision positioning, increasing the number of robot functions. This allows users to enjoy more robot services.

Benefits for Robot Device Providers

1. Robots access automatic production lines more easily, reducing cost and time of system integration.

2. Upper-level applications support real-time detection of lower-level devices' status and data, device fault reports, and statistical analysis and visualized management of device data, helping reduce the cost of data monitoring and collection for device providers.

3. Collects exception and fault information, implements self-diagnosis and analysis, remotely provides users with services, and solves problems to reduce unnecessary onsite services.

4. Controllers support multi-level offline control modes. A controller can normally execute daily planning tasks even if the uplink and downlink networks are faulty, ensuring system reliability.

5. Remotely obtains and statistically analyzes robot data to better support production services.

As industrial robots become more widely used, competition is heating up in the robot market. Improving business value of robots requires more competitive robots that are applicable to more scenarios. Edge computing controllers are designed as application integration platforms. For example, if a user uploads one of SIASUN's stacking technical packages to an edge computing controller, the robot has the stacking function. Similarly, if a data monitoring module is uploaded, the robot has the data uploading and monitoring functions. Users are also allowed to design and develop technical processes on edge computing controllers. That is, robot vendors' technical packages that comply with industry application standards and user-developed technical packages can be used to improve robots' production service quality and extend application scenarios of industrial robots, bringing more business benefits to the robot industry.

Edge computing controllers integrate robot services such as security, management, and smart diagnosis as standard services with which robot providers can effectively collect running data on robots and environments, monitor and manage robot products, extract much value from collected data, and improve quality of robots and robot services. The product management and analysis system based on industrial robot edge computing controllers can effectively help reduce costs of robots' after-sales maintenance and improve the quality of products and services. Therefore, edge computing controllers are also commercially beneficial in product management and after-sales services.

Edge computing controllers have the following social benefits:

▲Edge computing controllers support open application development and provide a platform for industrial robot resource construction and sharing. Edge computing controllers contribute to robot education, robot application scenario extension, and production automation improvement.

▲The robots with improved functions and usability can apply to more application scenarios to take on the strenuous and repetitive tasks people are unwilling to be engaged in, and allow people to do more creative work.