- About Us

- News

- Results Released

- Application Scenarios

- Resource Center

- Meeting

Elevator IoT test bed

Huawei Technologies Co., Ltd.

Schindler Management Asia Pacific (Shanghai) Co., Ltd

Currently, there are more than 15 million elevators running in various kinds of buildings around the world, and billions of passengers take elevators every day.

By 2050, 70% of the world's population will be living in cities, with about 3 billion people moving to cities in the next 20 years. After such a large number of people move to cities, more high buildings will be constructed to cope with the limited space, and elevators will play an increasingly important role in people's lives.

Currently, China is undergoing urbanization on a larger scale than any other country in the world. China accounted for 68% of elevators deployed worldwide in 2014.

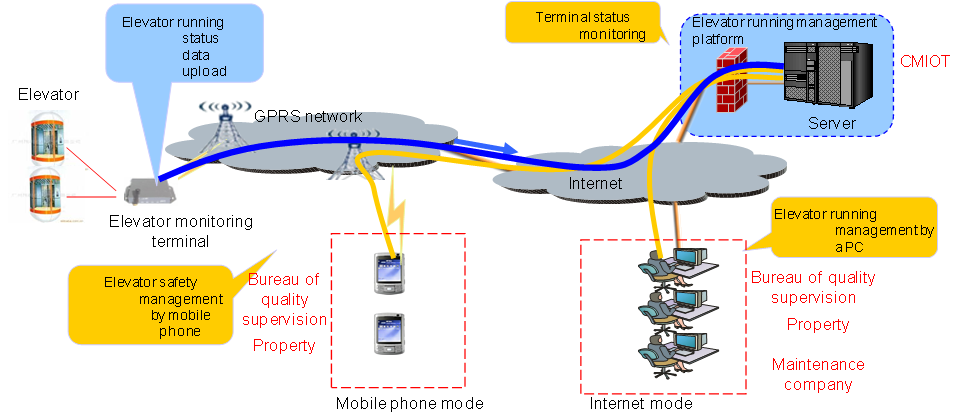

Traditional elevator systems are closed and cannot communicate with external devices.

▶ The elevator running safety status cannot be obtained in real time. The large number of elevators are widely dispersed and there are no effective technical measures to obtain the real-time running status of elevators. Elevator faults or accidents can only be reported by property management personnel, maintenance companies, or residents' complaints. There is much room for improvement in terms of elevator management.

▶ The capability of elevators to handle emergency faults needs to be improved urgently. The emergency systems vary between elevators, and communication measures are missing or outdated. As a result, there is no efficient rescue mechanism and some accident information cannot be reported immediately, delaying the rescue.

▶ Elevator management relies too heavily on manpower. The limited number of management personnel is unable to effectively manage the increasing number of elevators and elevator groups using traditional supervision methods.

Based on device-cloud synergy of cloud computing, the elevator IoT test bed collects elevators' running data in real time at the edge, and performs data preprocessing for elevators. The test bed is associated with the cloud-based Big Data analytics platform to comprehensively obtain health indicators of elevator components.

Huawei and Schindler jointly build the elevator IoT predictive maintenance test bed based on edge computing. The test bed helps elevator manufacturers transform from device manufacturers to service providers and create new profit growth points. Through elevator predictive maintenance, the test bed improves the elevator maintenance efficiency, reduces the maintenance cost, lowers the OPEX for end users, and promotes the production efficiency of enterprises.

Digital transformation of the elevator industry poses challenges to acquisition and transmission of data from many elevators.

The test bed uses advanced sensing technologies and edge network technologies to detect the elevator status and implement the following application scenarios.

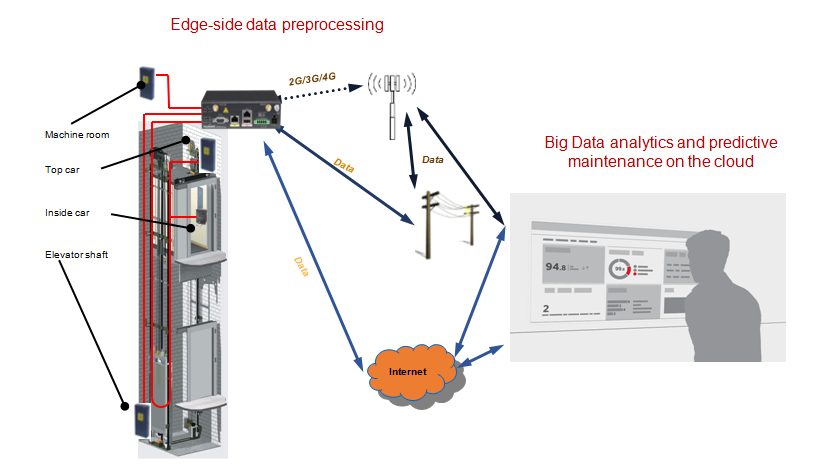

Scenario 1: Collaboration between the edge and cloud, and predictive maintenance analysis

• The edge gateway is integrated with the main control board or sensor of the elevator to collect the elevator running status data.

• The Big Data analytics platform runs in the edge gateway container to locally perform pre-analysis and processing of elevator running status data in real time.

• After data is preprocessed at the edge, it is uploaded to the cloud in wired or wireless mode.

• The cloud-based Big Data analytics platform performs predictive maintenance analysis and generates production reports, providing the basis for elevator maintenance decision-making.

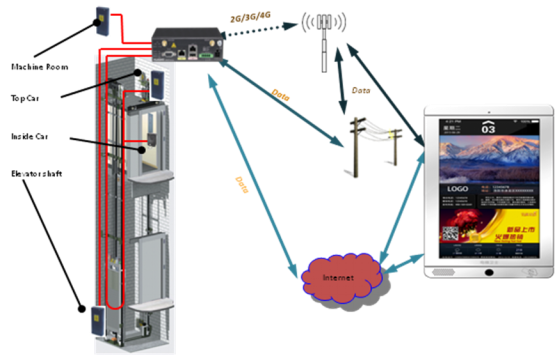

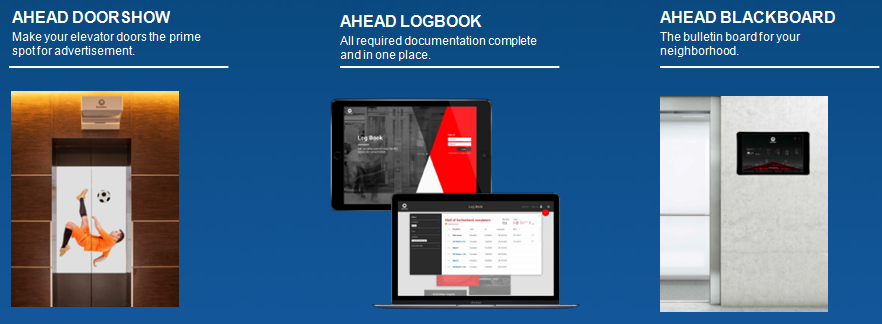

Scenario 2: Advertisement pushing and creating VASs based on elevators

• The test bed remotely manages release information on advertising screens, creating profit growth points.

• The cloud periodically delivers advertisement contents, and the edge gateway updates information in built-in advertising screen of elevators.

The test bed collects, analyzes, and processes elevator running data. The elevator IoT system implements final status detection, real-time analysis, fault diagnosis, and predictive maintenance. The test bed has the following features:

● Status detection: Learn elevator configuration parameters and running status in real time.

● Elevator availability analysis: Analyze the availability status and maintenance information based on the elevator running status.

● System maintenance and troubleshooting: Quickly locate problems, provide spare parts, and reduce downtime.

● Advertisement pushing: Push information in real-time and accurately, and update elevator advertisements.

The elevator IoT predictive maintenance solution brings great business benefits to the installed base markets and rapidly increasing markets, improves the service efficiency of manufacturers, and provides opportunities for ICT vendors to upgrade and reconstruct their edge networks. There are three benefits.

Benefit 1: 1. Implements elevator predictive maintenance and improves the operation efficiency.

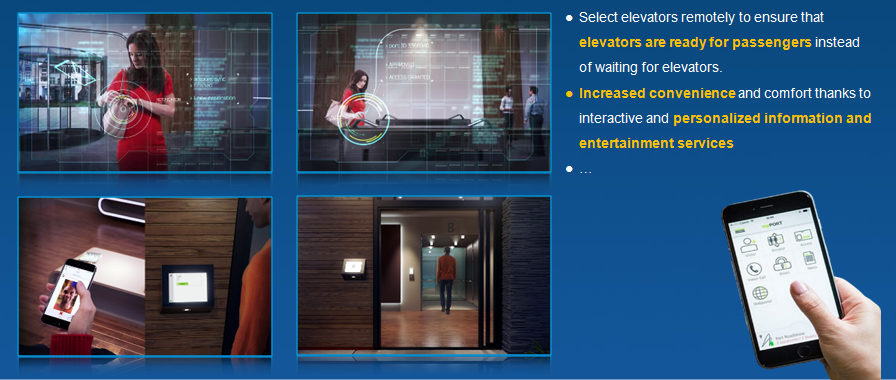

Benefit 2: Provides ultimate passenger experience and improves product competitiveness.

Benefit 3: Provides future-proof digital media and data value-added services.

Elevators are special devices. The safety of elevators is directly related to personal safety, and the maintenance of elevators determines their safety. Maintaining elevators is very important for an elevator company. Some elevator accidents in China occur because they are not maintained by professionally certified companies.

There are 15 million elevators worldwide, and the top four elevator manufacturers each maintain more than one million elevators. On average, each elevator does not work for two days every year due to faults or maintenance. The total downtime of elevators is 30 million days per year (15 million x 2).

In addition, each elevator is inspected twice a month, and the total inspection count is 360 million times per year (15 million x 2 x 12).

The elevator IoT predictive maintenance solution greatly saves labor costs, improves elevator maintenance efficiency and safety, reduces elevator accidents, and builds secure and comfortable working environments.